Congratulations to the 2024 Outstanding Chemical Engineer Award Recipients!

Congratulations to the 2024 Outstanding Chemical Engineer Award Recipients!

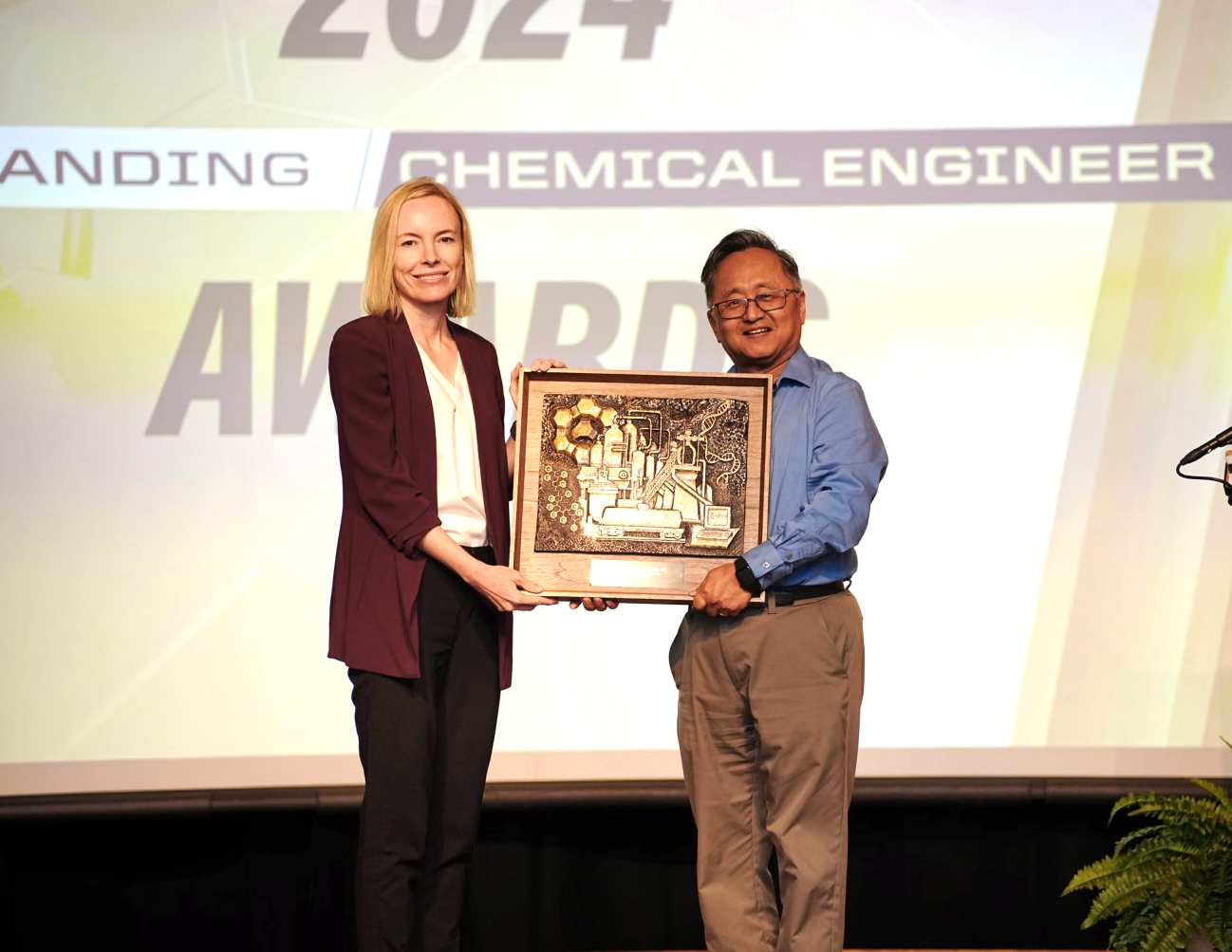

Every year since 1988, the Davidson School of Chemical Engineering has recognized alumni who have achieved distinction as leaders while making significant contributions to their fields. Over the years, only 163 of the School’s alumni have been accorded this prestigious award. On September 5, 2024, the Davidson School of Chemical Engineering held a banquet and awards ceremony to celebrate and honor two Purdue chemical engineers.

We are proud to add Alicia Gardner and Ray Mentzer as recipients of the 2024 Outstanding Chemical Engineer Award.

Meet the 2024 Outstanding Chemical Engineers

|

Alicia Gardner (BSCHE '01)

For her lifelong dedication to solving complex challenges in the biotech and pharmaveutical industry by delivering revolutionary patient treatments that enhance and extend lives.

|

|

Alicia Gardner credits her Purdue experiences in study abroad and the chemical

engineering co-op program for affirming her choice of major and her career. The

late Professor Robert Squires, who coordinated the co-op program for 30-plus

years, as well as former chemical engineering head, Robert Greenkorn, influenced

her greatly, as did the humble, but can-do attitude instilled by the Boilermaker

spirit.

“So many exciting doors opened, thanks to Purdue,” Gardner says.

A dedication to delivering new medicines to patients with serious and lifethreatening

diseases has been a driving force in Gardner’s career trajectory. As

senior vice president of commercial at Revolution Medicines, she leads a diverse

team charged with bringing innovative targeted cancer therapies to market. She

also serves on the company’s cross-functional executive leadership team and

contributes to its portfolio strategy to maximize patient and business impact.

Before joining RevMed, she was vice president at Genentech, a member of the

Roche Group. During her tenure there, she held a variety of leadership positions

working across the company’s oncology, hematology and COVID franchises in the

US, Switzerland and Canada. With more than 20 years of commercial experience

across biotech and pharmaceutical companies, Gardner has contributed to the

lifecycle management, strategy development, marketing and launch of several

commercialized drug therapies.

“At Purdue, I learned the value of teamwork, how to embrace challenging

problems and the importance of a well-balanced life,” Gardner says. And her

advice to today’s undergraduates is simple — “Stay curious and don’t be afraid to

take risks.”

|

|

|

|

|

|

|

Ray Mentzer (MSChE '76 | PhD '80)

For his lifelong commitment to developing and sharing industry expertise in chemical process safety and promoting best practices.

|

|

It took one year for Ray Mentzer to build the experimental apparatus central to his PhD research at Purdue. It took him two more years to get it to work. Undiscouraged, Mentzer relied on the dedication and strong work ethic imbued in the ethos of Purdue engineers to steadfastly pursue a goal despite challenges and setbacks. Now, as a professor of engineering practice at Purdue, Mentzer inspires his students to do the same.

Mentzer’s journey back to campus came after a 28-year career with ExxonMobil where he held more than a dozen assignments with the multinational oil and gas corporation, including posts in Houston, New Orleans and London, and responsibilities across the globe. He retired in 2008 as ExxonMobil’s Safety, Health, Environment and Security Manager, having managed a team of 150 who provided safety, environmental and security support for 16 international upstream projects, each costing more than $1 billion. He then spent seven years lecturing on process safety at Texas A&M University, where he was also deeply engaged in the Mary Kay O’Connor Process Safety Center, where he oversaw many graduate student research projects.

“Executive positions require good communication, persuasion and teamwork skills as well as reliance on others when delegating,” Mentzer says. “Understanding the 80-20 rule is imperative.”

He joined the Purdue faculty in 2016 where he teaches the required senior-level chemical process safety course to ~170 students. He is also the executive director of the Purdue Process Safety and Assurance Center, one of the few centers of expertise in the country dedicated to preparing students to prevent potential disasters and equipping them for success upon entering industry. The Center has over twenty industrial sponsors and typically conducts 25 research projects a year.

|

|

|

|

|

| The Plaque Honoring the Outstanding Chemical Engineers | |

This plaque was created in 1993 and has been awarded to all OChEs since then. Its centerpiece is a copy of the depiction of a sulfuric acid plant shown over the west entrance to Forney Hall. It represents the central and continuing role of chemical engineers in the design and operation of all aspects of chemical manufacturing. The computer screen in the lower right shows a differential equation. While it is meant to represent the fundamental modeling that chemical engineers do to extend fundamental understanding, explain observed phenomena and, most importantly, predict system behavior, the computer is also a reminder that chemical engineers use systems approaches to solve huge problems involving many variables and wide ranges of length and time scales. The double helix in the upper right represents the important role that chemical engineers are playing in the understanding and utilization of biological processes in medical and commercial applications. The artist’s rendition of the polystyrene chain in the lower left is a reminder that chemical engineers continue to develop new understandings and new processes that support the property refinement and ongoing growth of polymeric materials and maintenance of polymers as a cornerstone of the chemical industry. The structure in the upper left is that of Y-zeolite, the key component in the fluid catalytic cracking of crude oil to make gasoline. It is a reminder that rate processes and their catalytic acceleration are central to a chemical engineer's ability to accomplish the chemical transformations that produce valuable products, improve the environment, and fuel the world economy.

This plaque was created in 1993 and has been awarded to all OChEs since then. Its centerpiece is a copy of the depiction of a sulfuric acid plant shown over the west entrance to Forney Hall. It represents the central and continuing role of chemical engineers in the design and operation of all aspects of chemical manufacturing. The computer screen in the lower right shows a differential equation. While it is meant to represent the fundamental modeling that chemical engineers do to extend fundamental understanding, explain observed phenomena and, most importantly, predict system behavior, the computer is also a reminder that chemical engineers use systems approaches to solve huge problems involving many variables and wide ranges of length and time scales. The double helix in the upper right represents the important role that chemical engineers are playing in the understanding and utilization of biological processes in medical and commercial applications. The artist’s rendition of the polystyrene chain in the lower left is a reminder that chemical engineers continue to develop new understandings and new processes that support the property refinement and ongoing growth of polymeric materials and maintenance of polymers as a cornerstone of the chemical industry. The structure in the upper left is that of Y-zeolite, the key component in the fluid catalytic cracking of crude oil to make gasoline. It is a reminder that rate processes and their catalytic acceleration are central to a chemical engineer's ability to accomplish the chemical transformations that produce valuable products, improve the environment, and fuel the world economy.